Still pressing forward over here in the flatlands of East Anglia; ticking things off on the to-do list. First up this time is mirrors. I started off unsure what I was going to do, mainly because of that socking great air intake behind me. First thing though, was to fit the wing mirrors that the regs change from last year effectively now require. Here’s the driver’s side one. I must admit I don’t usually go on with these sorts of mirrors as they’re too prone to readjusting themselves. However, this time I tried to preclude this by not getting the swivel based ones so as to remove some of the degrees of freedom. My biggest worry about these at the moment is whether I can effectively see over the haunches of the rear of the car. For some reason I’m just incapable of working this out in the garage. I know that as soon as the car’s on track it’ll be dead obvious.

Still pressing forward over here in the flatlands of East Anglia; ticking things off on the to-do list. First up this time is mirrors. I started off unsure what I was going to do, mainly because of that socking great air intake behind me. First thing though, was to fit the wing mirrors that the regs change from last year effectively now require. Here’s the driver’s side one. I must admit I don’t usually go on with these sorts of mirrors as they’re too prone to readjusting themselves. However, this time I tried to preclude this by not getting the swivel based ones so as to remove some of the degrees of freedom. My biggest worry about these at the moment is whether I can effectively see over the haunches of the rear of the car. For some reason I’m just incapable of working this out in the garage. I know that as soon as the car’s on track it’ll be dead obvious.

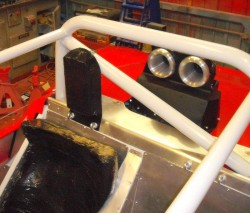

After some deliberation, I also decided to fit a bit panoramic mirror as well, like the one I used on the Fury. However, as the front of this roll cage is rather higher than the one on the Fury, I could position the mirror pretty much straight in front of me. I think this’ll make it easy to see and, hopefully, not too much of a distraction. Again, only time on track will tell.

After some deliberation, I also decided to fit a bit panoramic mirror as well, like the one I used on the Fury. However, as the front of this roll cage is rather higher than the one on the Fury, I could position the mirror pretty much straight in front of me. I think this’ll make it easy to see and, hopefully, not too much of a distraction. Again, only time on track will tell.

All that stuff about mirrors trips off the keyboard so easily you might wonder why this is all taking me so long. The problem is that I spend ages juggling things about, and sitting on the workbench musing about things, before actually drilling holes. At least that’s my excuse.

Next thing, although you might well notice that it isn’t really next, was to make a head restraint. Here it is in all its glory. Essentially it’s just a lump of steel retained by the harness mounts and that old stand-in, an exhaust clamp. I’ve put some lumps of alarmingly solid roll bar foam in front of this, held in place by that other old technique, some gaffer tape. This all makes a pretty solid and I’m pretty sure that it’s in an acceptable place. To be honest, the exact position of this is something else that it’s hard to work out before being out on track. I’m aware that as I’ve got quicker as a race driver I actually move my head around rather more. If you look at photos of the car at speed around a corner these days then I often have my head at quite an extreme angle. Hence I need to make sure that the restraint doesn’t impede me.

Next thing, although you might well notice that it isn’t really next, was to make a head restraint. Here it is in all its glory. Essentially it’s just a lump of steel retained by the harness mounts and that old stand-in, an exhaust clamp. I’ve put some lumps of alarmingly solid roll bar foam in front of this, held in place by that other old technique, some gaffer tape. This all makes a pretty solid and I’m pretty sure that it’s in an acceptable place. To be honest, the exact position of this is something else that it’s hard to work out before being out on track. I’m aware that as I’ve got quicker as a race driver I actually move my head around rather more. If you look at photos of the car at speed around a corner these days then I often have my head at quite an extreme angle. Hence I need to make sure that the restraint doesn’t impede me.

You may notice that I painted the steel matt black and I did the same thing to the injector cover that forms part of the induction device. My hope is that this makes things a little less obvious. Hard to tell really though, it does look quite neat though.

I then decided to redo something that I’ve done a couple of times recently and have a look at how the cooling was working. The last time I did this I wasn’t convinced that the fan was cutting in and out properly. So I tried it all again and there did seem to be a couple of problems. First of all, the fan was coming on rather late when the temperature at the engine was showing something like 105C (the pressure stops it boiling). Even when the fan did start up it then had a problem getting the temperature down. I suspect this is because it’s a long way to the radiator and the engine’s got up rather a head of steam, if you can forgive the curious metaphor.

Even when the temperature did start to come down it seemed as though the fan didn’t ever cut out. In this case the temperature at the engine end got down to 85C or so and the fan was still battering away. That seemed to show that there was rather too much hysteresis in the radiator mounted fan switch.

Even when the temperature did start to come down it seemed as though the fan didn’t ever cut out. In this case the temperature at the engine end got down to 85C or so and the fan was still battering away. That seemed to show that there was rather too much hysteresis in the radiator mounted fan switch.

Another problem was that I seem to be suffering from the odd leak. (If Anthea sees this I’ll get some stick as she always pulls my leg that plumbing things I do always leak. Of course, this isn’t true.) There’s an example of a small leak here with a little blob of coolant under the plumbing for the top hose. It’s not much, I know, but there shouldn’t be any at all. I’ve come to the conclusion that some of the hose clips are not very good quality, so I shall probably buy a bunch of better quality ones and check what they do. Mind you, I keep discovering little puddles on the floor and I’m bemused as to where these are coming from. Unless of course, it’s just condensation in the cold garage.

The other problem was every time the fan did cut in there was a little plume of steam from the radiator. This is clearly not right. The odd thing is that there doesn’t seem to be any evidence of the radiator itself leaking. Although, it could be that my policy of using a cheap radiator is starting to come home to roost. At the moment I’m seriously considering investing in a rather more expensive radiator. I did the same thing on the Fury to great effect.

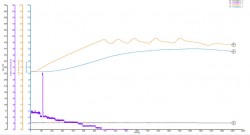

In the meantime I tried something else which was to wire the radiator from the ECU output which controls the fan on the bike. This entailed stringing a wire all the way from the back of the car to the front, nearly ruining all my plans for a super-organised loom, and requiring a relay by the radiator. However, the end result was rather encouraging. In this plot from the data logger you can see the temperature cycling up and down between about 88C and 95C which is much more satisfactory. What’s more, every time the fan started there seemed to be less steam. I’m now wondering if what I was seeing was condensation on the radiator boiling off. Seems odd though.

In the meantime I tried something else which was to wire the radiator from the ECU output which controls the fan on the bike. This entailed stringing a wire all the way from the back of the car to the front, nearly ruining all my plans for a super-organised loom, and requiring a relay by the radiator. However, the end result was rather encouraging. In this plot from the data logger you can see the temperature cycling up and down between about 88C and 95C which is much more satisfactory. What’s more, every time the fan started there seemed to be less steam. I’m now wondering if what I was seeing was condensation on the radiator boiling off. Seems odd though.

In the meantime, back to the now rather denuded to-do list. Here it is:

Pre test:

- Mount a camera somehow.

- Do a mega bolt check.

- Setup the suspension. This’ll have to be a guess at first but it’s a start. One issue with this is that I think I’m going to have to modify the little gadgets that extend the track rod ends as I think they’re a smidge too long.

Pre race:

- Think about adding additional triangulation to the engine compartment.

- Add some yellow.

- Get a lambda boss welded into the exhaust system. While this is being done, get the little fitting on the exhaust that I damaged re-welded.

- Add catalytic converter to tail pipe.

Long term:

- Duct radiator out of bonnet top.

- Come up with some way of making cockpit adjustable ARBs.

That means that really it’s time to start the setup. So, I’m going to have to drag fake-Tim out from lurking in the shed and start fiddling about with bolts and angles.