The engine’s now languishing in the corner of the garage. I need to work out what to do with it as it’s a completely fine engine really, although the gearbox probably needs a little work. Here it is looking all forlorn. Note, though, that it’s got my snazzy clutch actuating lever on the front of it. The engine’s now languishing in the corner of the garage. I need to work out what to do with it as it’s a completely fine engine really, although the gearbox probably needs a little work. Here it is looking all forlorn. Note, though, that it’s got my snazzy clutch actuating lever on the front of it. |

That leaves me with a big hole to fill with an engine. However, I’m sure there are going to be all sorts of problems fitting the engine so I’m probably going to end up doing several trial fits. While I’m here, it’ll be a good idea to clean the engine compartment up totally. I did notice that the POR-15 on the top chassis rail by the exhaust headers has suffered rather; I suspect it isn’t meant to be fried. I’ll have to think of some way of making it a bit more robust. That leaves me with a big hole to fill with an engine. However, I’m sure there are going to be all sorts of problems fitting the engine so I’m probably going to end up doing several trial fits. While I’m here, it’ll be a good idea to clean the engine compartment up totally. I did notice that the POR-15 on the top chassis rail by the exhaust headers has suffered rather; I suspect it isn’t meant to be fried. I’ll have to think of some way of making it a bit more robust. |

On then to the engine mountings. On then to the engine mountings.

The engine itself has some bushes cast into the block which are threaded at M12 fine. I’ve got some cap head bolts to go into these so I need to make something that the bolts will engage in.

The original Fisher approach to this was to forcibly tap the block to a coarse (and therefore more common) thread and to fit a flat plate to the block mounting bushes using a collection of small bits of tubing. Pretty poor approach, I always thought.

So, I’ve been meaning to sort this for a while. So, I made some of the things here, referred to as “bucket bushes”. This is just a bit of tubing with a plate welded across the end and a hole drilled through that plate. I have to say, having the lathe makes doing this sort of things spectacularly easier than it was before. For example, it’s easy to face the end of the tubing so that it’s exactly square and trivially easy to drill a hole dead centre of the end of the bush. |

So, with a couple of those each side of the engine I made mountings for the front and back of the end that looked like this. Of course, I now need to connect these up to the chassis somehow. That needs to wait, though, until I’m sure where the engine is going to go. So, with a couple of those each side of the engine I made mountings for the front and back of the end that looked like this. Of course, I now need to connect these up to the chassis somehow. That needs to wait, though, until I’m sure where the engine is going to go. |

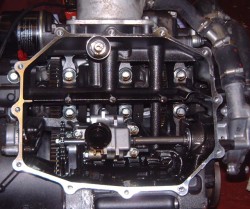

In order to know that, I need to attach all the various bits of gubbins to the outside of the engine. The first thing was the sump. So, I took off the original sump, and this is what it looks like inside. First impressions are that it’s pretty clean, which is good. The engine is only supposed to have done a few miles, and that certainly looks to be the case. Looking down the inlet ports and it looks new. In fact, the only sign of any sort of usage that I can see is that there’s a bit of grease around where the output sprocket is, and I suspect that appears pretty quickly once the bike’s ridden at all. In order to know that, I need to attach all the various bits of gubbins to the outside of the engine. The first thing was the sump. So, I took off the original sump, and this is what it looks like inside. First impressions are that it’s pretty clean, which is good. The engine is only supposed to have done a few miles, and that certainly looks to be the case. Looking down the inlet ports and it looks new. In fact, the only sign of any sort of usage that I can see is that there’s a bit of grease around where the output sprocket is, and I suspect that appears pretty quickly once the bike’s ridden at all. |

I wanted to get some sort of indication of what the oil temperature was, so I drilled and tapped the sump to take the same oil temperature sender as I used on the CBR900. The only problem with this sump is that it isn’t possible to get the sender right at the bottom as there isn’t a suitable flat location. Hence, I’m not sure that this position will actually work that well. Still, time will tell. I wanted to get some sort of indication of what the oil temperature was, so I drilled and tapped the sump to take the same oil temperature sender as I used on the CBR900. The only problem with this sump is that it isn’t possible to get the sender right at the bottom as there isn’t a suitable flat location. Hence, I’m not sure that this position will actually work that well. Still, time will tell. |

So, I put the sump on and put the engine the right way up again. That was a relief as the residual oil in the engine had run out and gone all over the floor. It’s going to take a while to clear it up. So, I put the sump on and put the engine the right way up again. That was a relief as the residual oil in the engine had run out and gone all over the floor. It’s going to take a while to clear it up.

In this photo I’ve also attached the adapter that moves the clutch slave cylinder out of the way of the propshaft adapter, and I’ve attached the adapter to the output shaft. |

With that done I could start a trial fit of the engine. I’m sure that I’m going to have to put the engine in and out several times until I know where it needs to be. At the first attempt it’s clear that the engine is really a small amount larger than the CBR900. As such it’s bound to be difficult. With that done I could start a trial fit of the engine. I’m sure that I’m going to have to put the engine in and out several times until I know where it needs to be. At the first attempt it’s clear that the engine is really a small amount larger than the CBR900. As such it’s bound to be difficult. |

And so it is. The first observation is that I can’t get the engine down as low as I’d like because the oil/water intercooler bashes in the chassis, as in the photo here. I want to mount the engine as low as I can. The main reason for this is so that the size of the bonnet bulge is reduced. The other reason is that it’s pretty easy to space the engine upwards slightly, but it’s close to impossible to lower it. So, by mounting it a bit low I’ll have a little room for manoeuvre. But, that clearly means chopping this chassis rail out. I’ll need to take the engine out again and work out how to do that. And so it is. The first observation is that I can’t get the engine down as low as I’d like because the oil/water intercooler bashes in the chassis, as in the photo here. I want to mount the engine as low as I can. The main reason for this is so that the size of the bonnet bulge is reduced. The other reason is that it’s pretty easy to space the engine upwards slightly, but it’s close to impossible to lower it. So, by mounting it a bit low I’ll have a little room for manoeuvre. But, that clearly means chopping this chassis rail out. I’ll need to take the engine out again and work out how to do that. |

There’s a similar problem at the top of the engine, where the gearbox-side mounts are pretty close to the top of my (specially widened) pedal box. I think I’m going to have to try reducing the width of the top of the pedal box slightly. I think that should be reasonably easy to do. There’s a similar problem at the top of the engine, where the gearbox-side mounts are pretty close to the top of my (specially widened) pedal box. I think I’m going to have to try reducing the width of the top of the pedal box slightly. I think that should be reasonably easy to do. |