Famous last words, or so they say. All the same, disregarding all the tribulations, sometimes I catch a glimpse of some part of the car (well, the bodywork really) and I think how pretty it is. I just hope I don’t bend it too soon…

Famous last words, or so they say. All the same, disregarding all the tribulations, sometimes I catch a glimpse of some part of the car (well, the bodywork really) and I think how pretty it is. I just hope I don’t bend it too soon…

I did manage to get the CVs off the driveshafts. Thanks for everyone that mailed me. In essence, it seems as though my shafts are pretty tight on the splines. I finally managed to get them off by holding the spring clip out of the way with some circlip pliers, assisted by a screwdriver, and using a hammer to tap the joint off the shaft. Actually, perhaps that should welt the joint off the shaft. Many people commented that it should drop off. There was no way on earth these were going to do that, even when my trusty assistant Adrian pulled and yanked on the joint it didn’t budge. It only moved when he hit it. That’s really what I’d been doing on my own, but having Adrian here was the big difference.

While I’m waiting for the new shafts, I’ve been pressing on with the final little bits and pieces. One thing I’d been fretting about for ages was whether the angle of actuation of the rear ARB links was right. A consequence of shifting up the top spring mounts has been that this was exacerbated. Hence I decided to move the ARB up. I did look for another place for it but decided that it had to stay here. So, I welded some little standoffs onto the chassis and shifted it up by a few inches. As a consequence I had to make some new drop-links (little items that require an age hunched over the lathe and a tap wrench to make). I thought I might as well do it properly now and have also finally got around to painting the bar, in this case matt black. I’ve quite got into painting things matt black, you seem to get a really nice finish with very little effort. Anyway, here’s what the suspension looks like, albeit without any driveshafts.

While I’m waiting for the new shafts, I’ve been pressing on with the final little bits and pieces. One thing I’d been fretting about for ages was whether the angle of actuation of the rear ARB links was right. A consequence of shifting up the top spring mounts has been that this was exacerbated. Hence I decided to move the ARB up. I did look for another place for it but decided that it had to stay here. So, I welded some little standoffs onto the chassis and shifted it up by a few inches. As a consequence I had to make some new drop-links (little items that require an age hunched over the lathe and a tap wrench to make). I thought I might as well do it properly now and have also finally got around to painting the bar, in this case matt black. I’ve quite got into painting things matt black, you seem to get a really nice finish with very little effort. Anyway, here’s what the suspension looks like, albeit without any driveshafts.

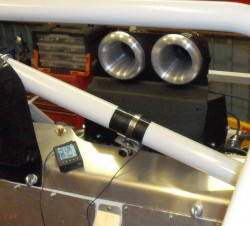

Long time readers will know that I like to video my races. Hence I needed to make a camera mount for the new car. Well, I didn’t need to make one I could have bought one for £50 or so. The attraction of making one at a total cost of about 10p, plus my zero-cost time, was quite attractive. Here’s the end result attached to the roll cage and just in front of what my friend Denis called the car’s ghetto blaster. This mount is essentially two bits of tubing, cut longitudinally in half, a flat bit of ally, some sticky foam and a few rivets and tie wraps. It doesn’t look super sexy but I reckon it’ll work fine. The one problem is that I’m not totally sure if it’ll be able to see over my shoulder. I can’t really check that without getting in the car and I’d have to remove fake Tim for that and I’d only have to put him back later.

The attraction of making one at a total cost of about 10p, plus my zero-cost time, was quite attractive. Here’s the end result attached to the roll cage and just in front of what my friend Denis called the car’s ghetto blaster. This mount is essentially two bits of tubing, cut longitudinally in half, a flat bit of ally, some sticky foam and a few rivets and tie wraps. It doesn’t look super sexy but I reckon it’ll work fine. The one problem is that I’m not totally sure if it’ll be able to see over my shoulder. I can’t really check that without getting in the car and I’d have to remove fake Tim for that and I’d only have to put him back later.

You can see the video recorder in the photo above. Because of the re-located data logger in  the J15 I’ve been able to put that inside the same lunchbox as the logger where I can reach it pretty easily. Hopefully, the microphone will work OK in there.

the J15 I’ve been able to put that inside the same lunchbox as the logger where I can reach it pretty easily. Hopefully, the microphone will work OK in there.

One thing I’ve been concerned about for ages is whether the tyres are going to clear the bodywork, which is always a problem on this sort of car. So, I took the springs off, again, and tried moving the suspension through its full travel. It’s interesting to do this as you can feel the camber recovery as you get to pull bump.

The rear tyres, it turns out, are fine. In the photo above the tyre is actually inside the bodywork which is fine. The front ones, though are a different kettle of fish and I’m going to have to be really careful with this. I’ve made a bit more clearance by grinding off the returns on the front wheel arches bit I may have problems at some circuits, exactly as I used to do in the Fury. Time will tell really.

Anyway, that all means that the current to-do list looks a bit like this:

Pre test:

- Install driveshafts,

- Duct air into radiator.

- Redo setup. (Everything will have changed by now.)

- Make/get some thrust washers to go under the rear hubnuts. As it stands the staking bit of the hubnut misses the staking groove.

Pre race:

- Think about adding additional triangulation to the engine compartment.

- Think about adding some yellow.

- Get a lambda boss welded into the exhaust system. While this is being done, get the little fitting on the exhaust that I damaged re-welded.

- Add catalytic converter to tail pipe.

Long term:

- Consider ducting radiator out of bonnet top. This depends on how well it cools and how hot my feet get.

- Come up with some way of making cockpit adjustable ARBs.

- Or, possibly, make some skinnier ARBs.