If you remember, I said I was bored with panelling. Well, I am so again. However, before moaning about that, here’s another picture of the diff assembly.

If you remember, I said I was bored with panelling. Well, I am so again. However, before moaning about that, here’s another picture of the diff assembly.

The only difference between this and the previous ones, is that I’ve made one of the spacers that hold the plates in the right position. Of the other two apices of the triangle, one will bolt to the rear engine mounting and the other will have another spacer, but one with a connection to one (or two, I haven’t decided yet) turnbuckles for getting tension in the chain.

Many thanks to everybody for their suggestions about the sprocket conundrum. The more I look at it, the more I think the sprocket was just not machined properly. Or, perhaps the diff wasn’t. Really, I should have tried the sprocket on the diff before splitting it, and I’ll try the other sprocket I have soon like that.

One thing though, is that I was talking to Andy about it yesterday at the 750 Motor Club awards do. He reckons that it wouldn’t actually have an effect and, oddly, I tried running a chain around the sprocket today and it seemed to run just fine. In fact I now understand all this even less!

By the way, with respect to the comments, you may notice that some people, like me, have a pretty little picture by their comments and other people have a rather bizarre symmetrical bitmap. If you’re commenting on this blog, and others, you might like to whizz off to the Gravatar site, where you can set up a “Globally Recognised Avatar”. That isn’t something to do with the ruler of the 3D blue cat people (I haven’t seen it, I’d rather poke my eyes out with a blunt stick) but a little picture that applies on lots of sites.

Anyway, I put the sprocket issue to one side and moved on. One aspect of this is that I picked up the driveshafts at the 750MC party. They’re the shiny ones here, next to my fabricated dummies. They’re made out of some special Swedish unobtanium steel and should work well. Yes, I know the new ones look as if they’re shorter, but that’s just parallax.

Anyway, I put the sprocket issue to one side and moved on. One aspect of this is that I picked up the driveshafts at the 750MC party. They’re the shiny ones here, next to my fabricated dummies. They’re made out of some special Swedish unobtanium steel and should work well. Yes, I know the new ones look as if they’re shorter, but that’s just parallax.

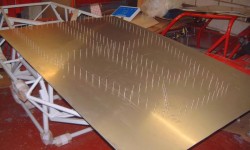

Unfortunately, it was time to get back to the panelling. Oh joy. First thing was to turn the chassis upside down and put the floor panel on. The plan is to completely cover the front part of the chassis, back to the front of the engine compartment, with a single piece of aluminium. I don’t actually know yet how big I want to make this at the front, so currently it’s the full width of the aluminium sheet. I’m planning on a lot of attention to the aerodynamics on this car and just throwing away plan area without using it seems daft. So, I just rivetted on like this. As you can see, there’s a lot of rivets here, this just wouldn’t work without an air riveter.

Unfortunately, it was time to get back to the panelling. Oh joy. First thing was to turn the chassis upside down and put the floor panel on. The plan is to completely cover the front part of the chassis, back to the front of the engine compartment, with a single piece of aluminium. I don’t actually know yet how big I want to make this at the front, so currently it’s the full width of the aluminium sheet. I’m planning on a lot of attention to the aerodynamics on this car and just throwing away plan area without using it seems daft. So, I just rivetted on like this. As you can see, there’s a lot of rivets here, this just wouldn’t work without an air riveter.

With the chassis back the other way up, I got stuck into refitting all the panels I made a couple of weeks ago. Only this time they were rivetted and bonded in, not just held in with clekos. As you can see, I’ve also bolted in the pedal box, this time using nylocs.

With the chassis back the other way up, I got stuck into refitting all the panels I made a couple of weeks ago. Only this time they were rivetted and bonded in, not just held in with clekos. As you can see, I’ve also bolted in the pedal box, this time using nylocs.

Next thing to do is to make the panels for the other side of the car. Although all of the panels shown here are rivetted in, I’m planning on using rivnuts for some of the other panels, so as to facilitate better access. In particular, I want to do that for the seat backs as I’ll need to get  access to the exhaust side of the engine.

access to the exhaust side of the engine.

Here’s another photo. The hole in the panel at the side of the pedal box is there so as to get access to the pedal box’s bearing shaft.